-min-main.jpg)

The Advanced Features of x-Glo LED Light Strips: Beyond Illumination in Tough Conditions

Some of the most challenging working environments in the world include mines and oil and gas facilities. Dangerous machinery, harsh and humid conditions, and hazardous chemicals are often involved, so close attention needs to be paid to safety measures. One of the most important safety features for tough conditions is lighting.

But, not just any lighting! Fluorescent and incandescent bulbs do not measure up to the illumination needs of these tough environments. Why? Because these old-school lighting solutions do not have the required durability and reliability for mines and oil and gas facilities.

This is where LEDs come in. The benefits of LED strip lights go beyond superior illumination. The x-Glo catalogue of products includes advanced features that make them stand out from the lighting crowd as the ideal solution for the harshest working conditions.

How Do LEDs Go Beyond Illumination?

Quality, reliable illumination is obviously one of the most important aspects of the x-Glo LED creation process. However, it doesn’t stop there. To achieve safe, robust, and durable lighting solutions, our factory's research and development team has listened carefully to feedback from end-users to understand their requirements.

These are the six key features of x-Glo LEDs that have resulted in our lighting solutions being installed in over 500 mines around the world:

Modular Design

The design of x-Glo light strips enables the strip light to be cut and joined at intervals of approximately 11 centimetres. This makes customization and adapting to unique needs simpler.

Five Year Warranty

x-Glo strip lights include inner protection layers that protect the LEDs, adding to a more durable and long-lasting product. The LEDs are also made with food-grade silicone and anti-dust properties. These design qualities enable us to confidently offer a five-year warranty on a full range of low-voltage strips.

Independent Testing

The x-Glo range has been subject to extensive independent testing and certification over the past decade to verify that the product is safe and suitable for installation in mining applications. The more than 30 test certificates verify that the light strip and its accessories are:

Flame retardant and self-extinguishing to European standards

Water and dust ingress protected

Corrosion-resistant

Devoid of hazardous substances

Devoid of harmful electromagnetic emissions

Tensile strength tested to European standards

Impact resistant

See x-Glo’s range of certifications here.

Thermal Management

This is a very important design element of LED light strips. x-Glo lights employ a thermal manager design to ensure the longest possible lifespan.

Dust Repellent

Dust can have a serious impact on the brightness of illumination. The x-Glo LED light strip PVC and silicone versions include nanotechnology that uses the Lotus Effect to repel dust from sticking to the surface, resulting in a reduced need for maintenance on the lights.

Maximum Flexibility In Run Length

The x-Glo light strip is designed to have maximum flexibility in the run length to suit the customer's requirements. Unlike competitor products that are only supplied in fixed lengths, for example, in 10-metre sections, the x-Glo range can run for extra-long run lengths of up to 168 metres, which can significantly reduce installation costs.

All of these advanced features contribute to an LED light that is long-lasting and needs very few replacements and little maintenance. This makes x-Glo a more cost-effective and sustainable choice, which is further enhanced by the fact that our lighting systems are recyclable. x-Glo contributes to more sustainable mining operations.

Real-World Applications

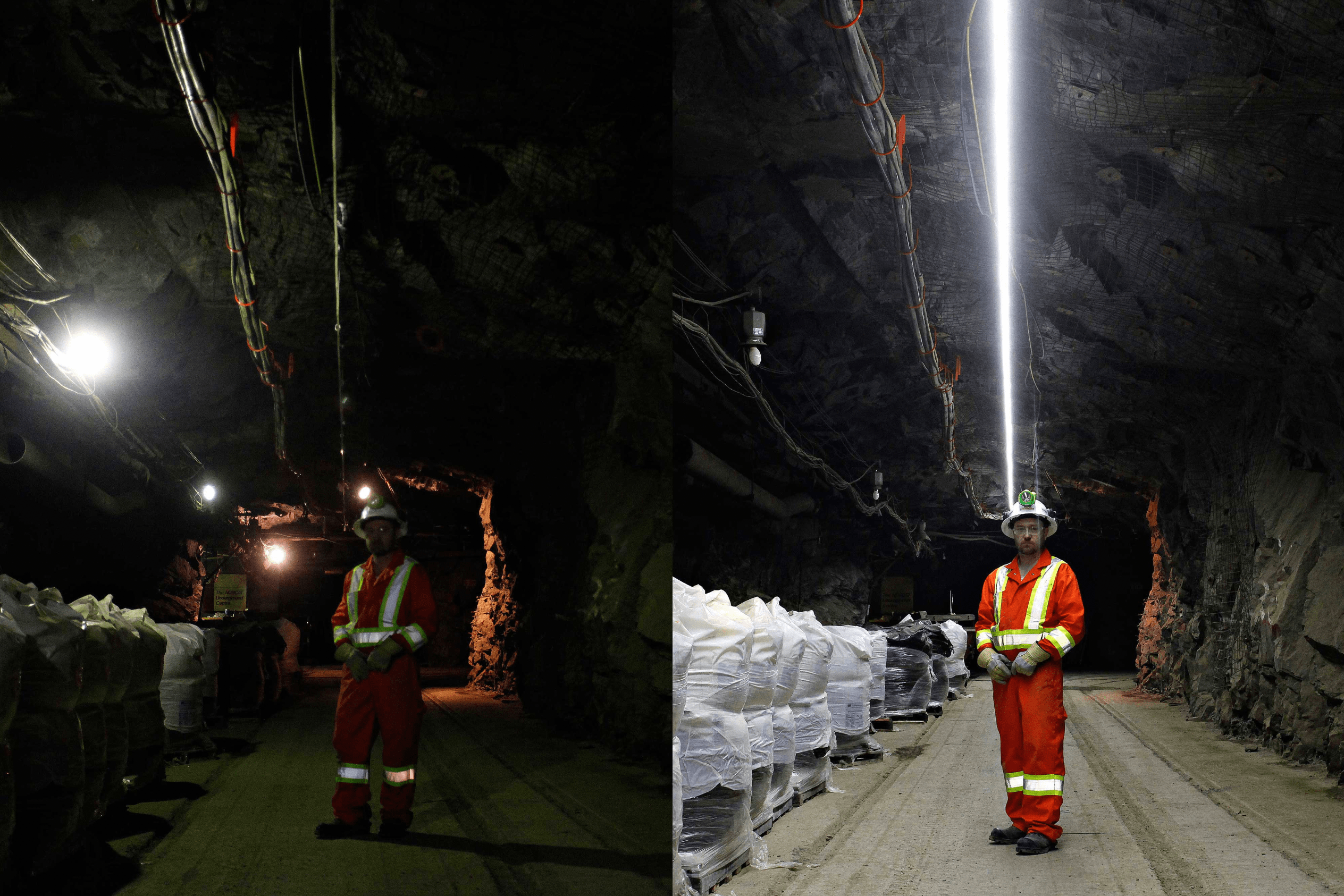

Let’s see how x-Glo LEDs are lighting up mines around the world in these before and afters from Zambia, Canada, and the USA: